If we are ever to reduce the quantity of plastics being dumped into the environment, efficient recycling is essential. Currently, many plastics cannot be economically sorted to enable their recycling. For example, many plastics contain flame retardants to increase their resistance to ignition, reduce flames spreading, minimise smoke formation and to prevent the plastic from dripping. The amount of flame retardant added to plastics and the type used can vary considerably, due to the need to tailor the plastic to its particular application and to meet safety standards. However, only plastics of the same type and with similar flame retardants can be recycled together. Therefore, before recycling can occur, plastics need to be sorted, not only by the type of plastic (acrylonitrile butadiene styrene and polystyrene in this study) but also by any flame retardant added. Without sorting, recycling cannot take place.

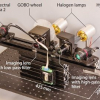

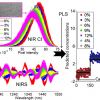

In a paper published in JSI—Journal of Spectral Imaging (doi: https://doi.org/10.1255/jsi.2019.a1), José Amigo and co-authors detail a method using near infrared hyperspectral imaging and chemometrics that can sort between different types of plastic and between different additions of flame retardant. Using an imaging technique for this recycling application is important, since it can identify individual pieces of plastic and any flame retardant they may contain from among many others, for example, on a conveyor belt in a recycling plant.

For optimum performance, any sorting technique needs to be fast and able to identify accurately the wide range of combinations of plastic and flame retardants it may encounter. The system reported in the JSI—Journal of Spectral Imaging paper uses the Decision Trees chemometrics technique combined with spectral data obtained from near infrared hyperspectral imaging and is able to distinguish between different plastics and flame retardants within them with 100 % accuracy.

José Amigo commented “Recycling plastics has been studied for many years. Indeed, some commercial cameras separating a limited number of plastic types have been available for some time. However, in this research, we wanted to go a step further to separate plastics containing flame retardants. Moreover, the proposed methodology was tested with real samples that can be found in current recycling lines.”